What is KiTEC composite pipe?

KiTEC composite pipe is having an aluminium tube bonded with outer and inner PE layer by using special purpose adhesive.

The tie layers are formed by this adhesive. Because of these tie layers, the pipe, when used for recommended operating

temperature range of –40o to 95o C. , acts as a single component pipe and not as a multi-layer pipe.

What is the difference between braded hoses and composite pipes?

In case of braded hoses, the metallic reinforcement is provided to increase the structural strength of the hose. This reinforcement by itself can not withstand pressure.

In case of KiTEC composite pipes, the aluminium tube is formed and welded online. This ensures that the aluminium tube functions as a pipe and increases the pressure

withstanding property of the composite pipe. The increase in structural strength is also achieved as in case of braded hoses.

Coefficient of thermal expansion is different for Aluminium and PE. What is the effect of these varying coefficients of thermal

expansion on the performance of KiTEC Composite Pipe, when used for fluids having operating temperatures other than ambient?

Because of tie layers, PE layers and aluminium tube function as single component pipe for operating temperature range of –40o to 95o C.

This ensures that there is no differential expansion of PE layers and aluminium tube. The resultant expansion coefficient is very low and approx. same as that of copper pipe.

Scaling does not take place in KiTEC composite pipes. Why?

Inside surface of KiTEC composite pipe is very smooth. In addition to this, because of inherent properties of PE, there can not be any bonding between PE and the minerals.

Hence the minerals, which are separated from the stagnant water, can not stick to the wall of the pipe. When the flow starts, the minerals are flown out of the piping system.

What is the bending radius for KiTEC Composite pipes? Why bending radius is so low as compared to conventional PE pipes? What is the

effect of tensile and compressive stresses developed on outermost and innermost layer of the pipe cross section, respectively, on the performance of pipe?

The minimum bending radius for KiTEC composite pipes is 5 times the outside diameter(OD) of pipe.

The bending radius is low because of following factors.

The tensile and compressive stresses developed on outermost and innermost layer of the pipe cross section, respectively, are well within the allowable

limits when the bending radius is more than or equal to 5 times the OD of pipe. Hence, the pipes bent within this limit are safely used without any reduction in basic strength of pipe.

What is operating temperature range for KiTEC Composite pipes?

KiTEC composite pipes can withstand multiple freezing cycles. KiTEC composite pipes, being flexible, can withstand the stresses, developed due to increase in volume because of formation

of ice at subzero temperature. PE as well as aluminium does not loose any strength at sub-zero temperature upto –40o C. Hence, the recommended min. operating temperature is –40o C.

For hot water, KiTEC composite pipes are designed for 10 bar pressure at 60o C. Temperature. For hot water application, KiTEC pipes are used up to 80o C. temperature when the

pressure is less than 4 bar. Maximum allowable short term increase in temperature is 95o C.

What is the recommended insulation thickness, as compared to conventional metal pipes, for KiTEC composite pipes when being used for hot water or for fluids having operating temperature less than ambient?

KiTEC pipe is bad conductor of heat. Hence the insulation thickness required is less as compared to metal pipes. Approximate equivalent insulation thickness can be calculated as follows:

The outside diameter(OD) of insulation pipe in case of KiTEC will be 60% of the OD of insulation pipe required for equivalent metal pipe. Thus, for example, for 0.5 inch NB GI pipe if the insulation

pipe OD is 100 mm, 60 mm OD insulation pipe for 1216 KiTEC will give the same results.

What is the recommended insulation for KiTEC pipes when used for hot water in concealed piping?

In case of concealed piping, it is recommended not to provide any insulation. In case of metal pipes, the insulation is provided for following reason:

- As the conductivity of metal pipes is very high as compared to tiles/plaster covering the pipe, the differential temperature leads to

discoloration of tiles. In many cases, this may lead to cracks in the wall. Hence, some insulation is required to be provided.

In case of KiTEC pipe, due to low thermal conductivity, this phenomenon does not occur and hence insulation is not required to be provided.

Why KiTEC composite pipes are suitable for some fluids such as Diesel / petrol / fuel oils?

(PE pipes are not recommended to be used for these fluids.)

Conventional PE pipes are weakened due to swelling when they come in contact with these chemicals, leading to failure of pipe.

In case of KiTEC composite pipes, because of bonded aluminium tube, the swelling does not take place. Hence, KiTEC composite pipe does not loose any

strength when used for these chemicals. As aluminium itself does not come in contact with fluid, chemical reaction of the chemicals with Aluminium is ruled out.

KiTEC composite pipes are not recommended to be used for chlorinated solvents. What is the effect of chlorine used for water treatment in case of potable water?

Conventional PE pipes are weakened due to swelling when they come in contact with these chemicals, leading to failure of pipe. In case of KiTEC composite pipes,

because of bonded aluminium tube, the swelling does not take place. Hence, KiTEC composite pipe does not loose any strength when used for these chemicals.

As aluminium itself does not come in contact with fluid, chemical reaction of the chemicals with Aluminium is ruled out.

Inside diameter of KiTEC pipes is less as compared to equivalent GI pipe? Why?

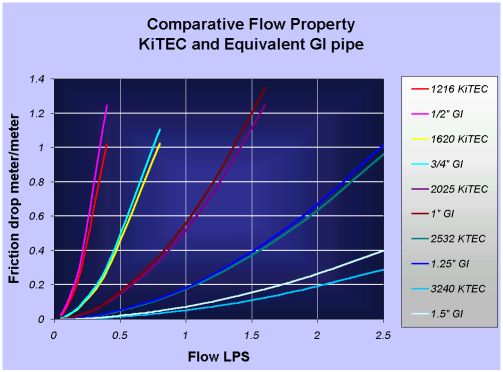

KiTEC pipe is having smooth inside surface and hence is having better flow property as compared to GI pipes. The calculations for equivalent pipe sizes are as follows:

The graph is based on Hazen William’s Flow Equation. It can be seen that the flow carrying capacity of KiTEC is higher than equivalent GI pipe. The formula is as follows :

Q = F0.54 x 1002 x C x D2.63

Where,

| Q = |

Water Flow Rate |

Cubic Meter per Hour |

| F = |

Friction drop |

Meter per meter |

| C = |

Surface factor |

For KiTEC C = 150 For GI C = 100 |

| D = |

Inside Diameter of Pipe |

mm |

What is the recommended clamping distance for KiTEC composite pipes when installed externally for hot water?

The clamping distance remains same for cold as well as hot water.

Is there any special clamping required when KiTEC pipe is used for concealed installation?

As the coefficient of thermal expansion is very low, no clamping is required to arrest the expansion of the piping. The stresses are also very low (same as that for copper pipe).

As KiTEC is totally malleable and does not have any spring back action once formed into curves, it is not required to provide any special clamping to keep the pipe in place. Considering both these points, it is not required to provide any special clamping for installation of KiTEC pipes in concealed installation.

What is the effect of reduction in bore at the fittings when internal sealing fittings are used?

The friction loss across the internal sealing fittings is higher as compared to external sealing fittings. However, as the fittings required are less in comparison with GI pipes, it does not affect the overall size selection.

What is the life expectancy of 'O' rings used with KiTEC fittings? WHy?

Material composition: The ‘O’ rings are made from SILICONE RUBBER. Salient features of Silicone rubber are as follows:

Salient Features:

- Permanent Set: At all the values of hardness the Permanent Set is extraordinarily low. In this respect, it is superior to all other elastomers.

- Heat resistance: Silicone is permanently resistant and remain elastic without any appreciable change in other mechanical properties for a temperature range from –100oC. to 250oC.

- Resistance to aging, weathering and ozone: Silicone is unusually resistant to weathering of every description including action of ozone, oxygen, ultra violet rays and sunlight.

High aging resistance at elevated temperature is one of the main reason for use of silicone.

- Material tests: GE Silicone grade, EP8160/60U or equivalent is used for manufacturing the ‘O’ rings. The aging properties, as given by GE Silicones, are as follows:

*Heat age at 225

oC. temperature for 70 hours test as per ASTM D-573:

Suitability for fittings:The fittings are tested for type test, when assembled with these ‘O’ rings as per BS 7291:Part 1:1990 (Thermoplastics pipes and associated fittings

for hot and cold water for domestic purposes and heating installations in buildings.) The test is as follows:

Temperature: 60

oC.

Medium: Water

Pressure: 3.5 Kg/Cm^2

Duration: 3000 hours

The fittings with these ‘O’ rings pass this test and hence are termed to be suitable for hot and cold water for domestic purposes and heating installations in buildings.

What is the effect of UV radiation on KiTEC composite pipes?

Coloured KiTEC pipes are also UV stabilized. However, the UV stabilizers for coloured pipes can stabilize

the pipes but not for the design life span. the effect of UV radiation is limited to outer PE layer only.It is not recommended to use coloured pipes for

the applications where the pipe is directly exposed to sun rays. These pipes can be installed externally if they are not exposed to direct sun rays, as in case of external piping inside the toilet block.

Can coloured KiTEC pipes be used for external installations?

Coloured KiTEC pipes are also UV stabilized. However, the UV stabilizers for coloured pipes can stabilize the pipes

but not for the design life span. the effect of UV radiation is limited to outer PE layer only.It is not recommended to use coloured pipes for the applications where the pipe is directly exposed to sun rays.

These pipes can be installed externally if they are not exposed to direct sun rays, as in case of external piping inside the toilet block.